In collaboration with our strategic partners, we offer comprehensive solutions including the sale and rental of downhole tools, cable sales, and cable injection services to help clients optimize their CAPEX and OPEX. Additionally, we provide expert maintenance and repair services for downhole tools & equipment. ALG proudly serves as an authorized agent, hands on partner and distributor of a renowned international downhole tools manufacturers in the Middle East GeoMarket.

CT Multi-Lateral Exit Tools

- Hydraulic Knuckle

Controllable

incline up to 15°Fully sealed

through bore Pressure indication on

surface

- High Torque Indexer

Rotates

heavy BHAs by 15° – 45° By flow rate

and tension / compression

Repeatable for multi-laterals

Milling Tools

The Sealed Motor is class leading in flow limits and strength capabilities.

Over 25 years of motor engineering have allowed us to develop a bearing

section that is designed to take the highest flow and greatest torque

power sections available.

- Motor Specifications

| OD: | 2 7/8" | 73.0 mm |

| Length: | 61" | 155 cm |

| Weight: | 72 lbs | 33 kg |

| Maximum Flow Rate: | 250 GPM | 950 LPM |

| Maximum Weight on Bit: | Standard: 15,235 lbs | 6,777 daN | Tandem: 19,370 lbs | 8,616 daN |

| Bit Overpull: | Operating: 15,235 lbs | 6,777 daN | Re-Run: 38,300 lbs | 17,037 daN |

| Tensile Yield: | 145,000 lbs | 64,499 daN |

| Torque Yield: | 2,100 ft-lbs | 2,847 N-m |

| Connections: | 2-3/8" PAC |

- FEATURES & BENEFITS

| Key Features | Key Benefits | ||||

| Fully sealed bearing section | Redundant seals ensure that there is no contamination, providing long service life. | ||||

| Larger I.D. | With lower flow velocities* than leading competitors, the Talon Sealed Motor allows for greater pumping volumes, while minimizing erosion. | ||||

| Custom Bearings | Multiple bearing options allow for extreme W.O.B. capacities. | ||||

| Tough Flexshaft | Using higher strength alloys, our flexshaft sees better fatigue resistance than that of the industry standards. | ||||

| Dual Catch Design | Both rotor and internal catches make sure nothing is ever left in the hole. | ||||

| High Yield | Use of engineered connections, hardness coatings, and high strength alloys enhance fatigue resistance and reduce ownership costs. | ||||

| Tapered Connections | Engineered to have exceptional fatigue life. |

The Open Motor’s robust mud-lubricated design means longer life and lower cost of ownership.

Over 25 years of motor design experience has led to us to developing a motor capable of taking some of the highest torque on the market, while also being a simple design that is able to be serviced in almost any shop.

- Motor Specifications

| OD: | 2 7/8" | 73.0 mm | |

| Length: | 41" | 104 cm | |

| Weight: | 59 lbs | 27 kgg | |

| Maximum Flow Rate: | 225 GPM | 850 LPM | |

| Maximum Weight on Bit: | 17,500 lbs | 7,784 daN | |

| Bit Overpull: | Operating: 17,500 lbs | 7,784 daN | Re-Run: 59,000 lbs | 26,245 daN |

| Tensile Yield: | 126,000 lbs | 56,048 daN | |

| Torque Yield: | 2,010 ft-lbs | 2,725 N-m | |

| Connections: | 2-3/8" PAC |

- FEATURES & BENEFITS

| Key Features | Key Benefits | ||||

| Power Section Compatibility | Engineered to support the highest torque and highest flow power sections available, allowing you to achieve the greatest performance with confidence in your bottom end. | ||||

| Easy Servicing | We design our tools with easy, and low-cost servicing in mind, keeping downtime short. | ||||

| Heavy-Duty Bearing Pack | The high-capacity bearing pack allows you to run longer than others on the market under the toughest drilling conditions. | ||||

| Tough Flexshaft | Higher strength alloys within our flexshaft provide the highest fatigue resistance and durability in the industry. | ||||

| High Yield | Engineered tapered connections made from high-strength alloys have been hardness coated to better the fatigue resistance and provide confidence in today's extreme environments. |

Flow Diverter: the robust, flow-activated, and resettable answer to wellbore cleanout.

- FEATURES & BENEFITS

| Key Features | Key Benefits | ||||

| Repeated Use | With no need for a drop ball, the Talon Flow Diverter can be activated and reset as much as needed without slowing production. | ||||

| Ball Drop Bypass | A ball drop bypass is in place so that you can still activate the below tools. | ||||

| Fluid Compatibility | Not all wells are the same, the Talon Flow Diverter can take on a wide range of pumpable fluids. | ||||

| 100% Diversion | Once activated, 100% of the flow is diverted to the annulus. Along with the high jetting velocity, the Talon Flow Diverter can take on any cleanout. | ||||

| Reliable Sealing | Using Leading Developers in sealing, the Talon Flow Diverter is trusted to last multiple activation and hard agitations. | ||||

| High Yield | Use of engineered connections, hardness coatings, and high strength alloys enhance fatigue resistance and reduce ownership costs. | ||||

| Ergonomic Design | Engineered for easy maintenance and low servicing costs. |

- Operation Specifications

| OD: | 27/8" | 73.0 mm | 3 1/8" | 79.3 mm |

| Activation Flow Rate w/Freshwater: | 4 BBL/min | 650 LPM | 5.7 BBL/min | 900 LPM |

| Resetting Flow Rate w/Freshwater: | 2.8 BBL/min | 450 LPM | 3.8 BBL/min | 600 LPM |

- Tool Specifications

| OD: | 2 7/8" | 73.0 mm | 3 1/8" | 79.3 mm |

| Length: | 39" | 99 cm | 42" | 106 cm |

| Weight: | 45 lbs | 20 kg | 49 lbs | 22 kg |

| Tensile Yield: | 194,000 lbs | 86,295 daN | 220,000 lbf | 97,860 daN |

| Torque Yield: | 4,000 ft-lbs | 5,423 N-m | 5,000 ft-lbs | 6,779 N-m |

| Connections: | 2-3/8" PAC | 2-3/8" REG |

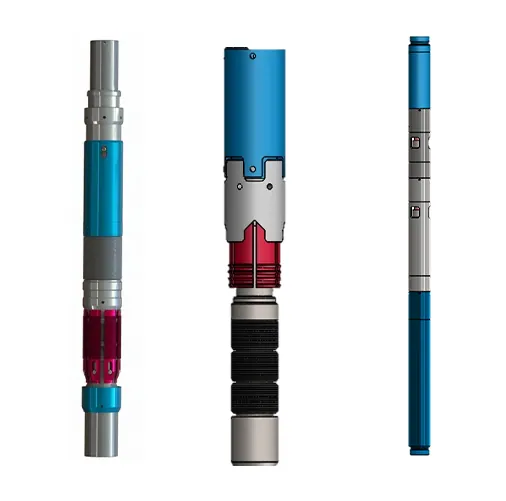

Cable deployed ESP Safety Valves

- Production Enhancement Safety Valve

Safety system for cable deployed ESP or CT Jet Pump

- SP Series Safety Valve (SPSV)

- Latch System

- Packer, then ESP / SPSV assembly

- Packer, then SPSV, then ESP

- ESP / SPSV / Packer run as one assembly

- Packer (E-line IX platform) Can be deployed in multiple configurations

Safety Valve Specs

- Features & Benefits

- Failsafe – opens only when ESP is activated.

- API 14A certified

- Prevents back spin of permanent magnetic ESP motors.

- Metal to metal gas tight valve seal.

- Reliable mechanical design with no electrical power, control lines or atmospheric chambers.

- Patented pressure boosted seal in both directions which allows surface pressure test.

Cable deployed ESP Safety Valves

| Model | SP217 | SP263 | SP319 |

| Working Pressure Rating | 5000 psi / 345 bar | ||

| Make up length * | *4ft/1m | 4ft/1.2m | 54" / 1.4m |

| Outside diameter | 2.17"55.1mm | 2.625" 66.7mm | 3.19" 81.9mm |

| Weight | 19lbs 9kg | 40lbs 18kg | 75lbs 34kg |

| Design setting depth | Limited only by ESP design depth | ||

| Design temperature rating | Standard: 150°C / 302°F High Temp: 170°C/338°F | ||

| Flow Area | 0.33 in² | 0.78 in² | 1.59 in |

| Design flow rates | TBC | 2000 bbl / day | 5,000 bbl / day |

| Connections | Customer specified | ||

| Available metallurgies | Customer specified - 4140, 13Cr, Inconel 925 etc |

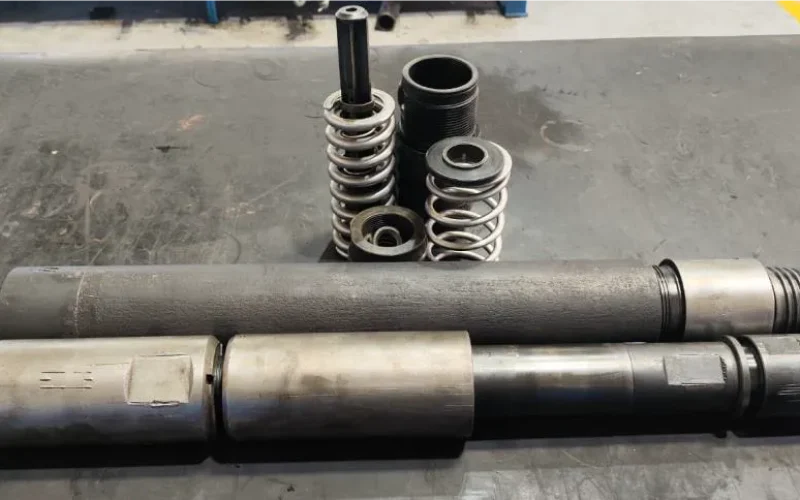

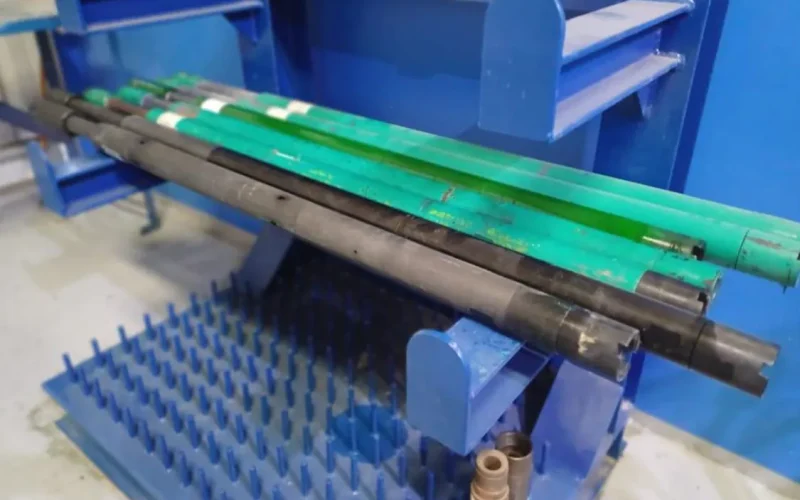

DOWNHOLE TOOLS WORKSHOP

ALG provides maintenance and repair services for downhole tool equipment and products at our state-of-the-art facility in Abqaiq. We deliver comprehensive solutions for tool quality maintenance and repair, utilizing the latest technologies, mobile workshops, and highly skilled technicians. Our certified experts are equipped to support service companies using DTI tools, offering services such as tool redress, troubleshooting, inspection, and repairs, while also providing training for technicians.