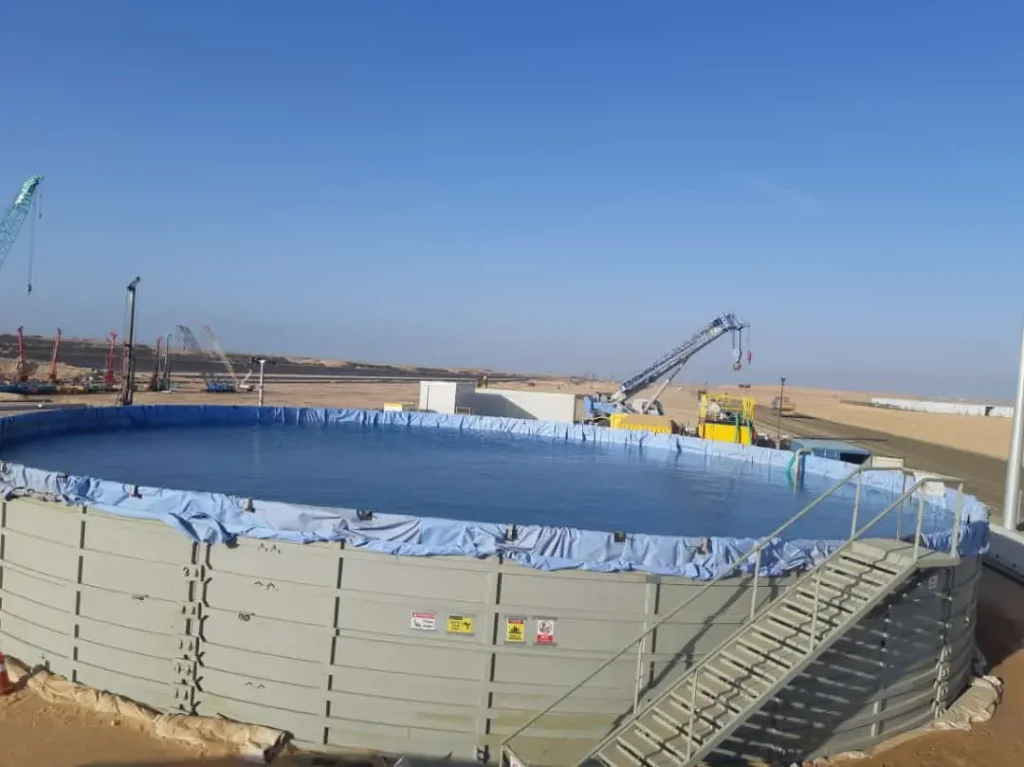

- AGST is a tank made from Carbon Steel based on ASTM A 36, ASTM A500 with welding inspection ASME SE IX.

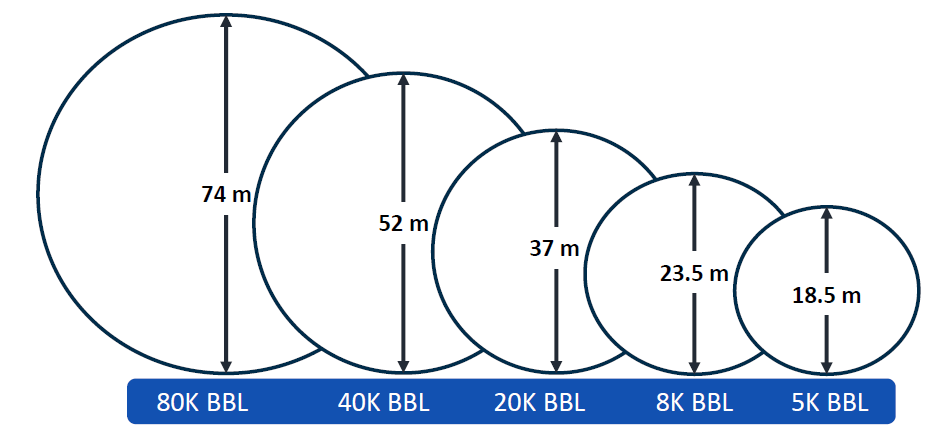

- AGST is available in different capacities: 80K, 40K, 20K, 8K & 5K; all have a height of 3m when rigged up.

- AGST is available in different capacities: 80K, 40K, 20K, 8K & 5K; all have a height of 3m when rigged up.

One-Stop Shop with a Single Point of Contact for Seamless End-to-End Service.

Capability to prepare the next site by filling a tank with water before relocating the FRAC fleet.

Reduced the number of water well to be drilled

Ability to rig up and fill the tank prior to site mobilization, reducing setup time and expediting operations.

Reduce CO2 Emission

Lower CAPEX/OPEX for clients as the contractor owns the assets.

Safety and environmental advantages.

Reducing logistics costs through the replacement of FRAC tanks and a centralized pumping network.

Faster mobilization and demobilization

Ensured continuous water flow to the site for CT, FRAC, Wireline, Testing, and Drilling operations.

Fewer trucks required; 4 flatbed loads or less, depending on the size of the AGST.

Higher efficiency by feeding multiple operations from a single central storage facility.

Continuous 24/7 pumping operations with real-time monitoring of water feed.

Reducing the number of crew teams required.

One-Stop Shop with a Single Point of Contact for Seamless End-to-End Service.

Reduced the number of water well to be drilled

Reduce CO2 Emission

Safety and environmental advantages.

Faster mobilization and demobilization

Fewer trucks required; 4 flatbed loads or less, depending on the size of the AGST.

Continuous 24/7 pumping operations with real-time monitoring of water feed.

Capability to prepare the next site by filling a tank with water before relocating the FRAC fleet.

Ability to rig up and fill the tank prior to site mobilization, reducing setup time and expediting operations.

Lower CAPEX/OPEX for clients as the contractor owns the assets.

Reducing logistics costs through the replacement of FRAC tanks and a centralized pumping network.

Ensured continuous water flow to the site for CT, FRAC, Wireline, Testing, and Drilling operations.

Higher efficiency by feeding multiple operations from a single central storage facility.

Reducing the number of crew teams required.

Steps Through Water Processes

STEP 1 HOSES AND REELERS

- HOSES

- Sizes: Ranging from 6″ up to 12″ diameter

- Blend of Nitrile Rubber and PVC

- UV Resistant

- H₂S Resistant

- Burst Pressure: 42 bar

- Wall Thickness: 3.8 mm

- Operating Temperature: Ranging from -30°C to +75°C

- REELERS

- Skid-mounted vertical reeler system, complete with hydraulic power pack, driven by a diesel engine.

- Removable heavy duty hose reel cassette, complete with storage cradle and lifting beam.

- Separate hydraulic oil tank.

- Hose deployment and retrieval from rear of skid.

- Cassettes to store 6 x 200 metres x 6” diameter lay-flat hose with couplings or 4 x 200 metres x 8” lay-flat hose with couplings.

STEP 2

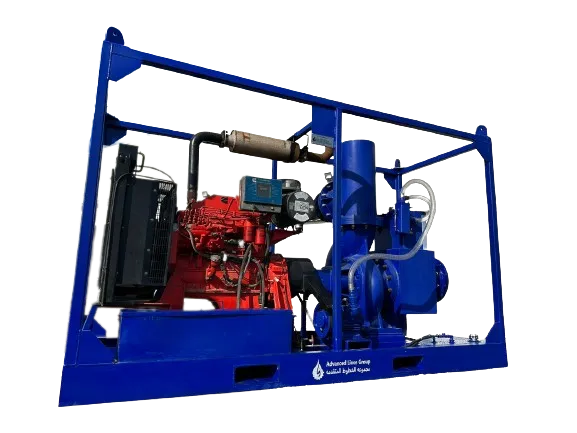

- BOOSTER PUMP

- Customized Booster pump, providing the required operation system to transfer water from the AGST to the fracking site.

- Sizes: 8″ to 12″ Pump or as per Client required. Capacity range: 60 – 80 BBL/Min or as per Client required

STEP 3

- ABOVE GROUND STORAGE TANK

- Capacity: Ranging from 5,000 BBL to 80,000 BBL

- Capable to operate in Extreme Weather Conditions

- Resistant to handle H2S content

- A superior grade of Water-Proofing Membrane

- Operating Temperature: up to +70°C

- Warranty of 10 Years on Manufacturing Defects

Water Transfer Capabilities

(WATER SOLUTIONS)

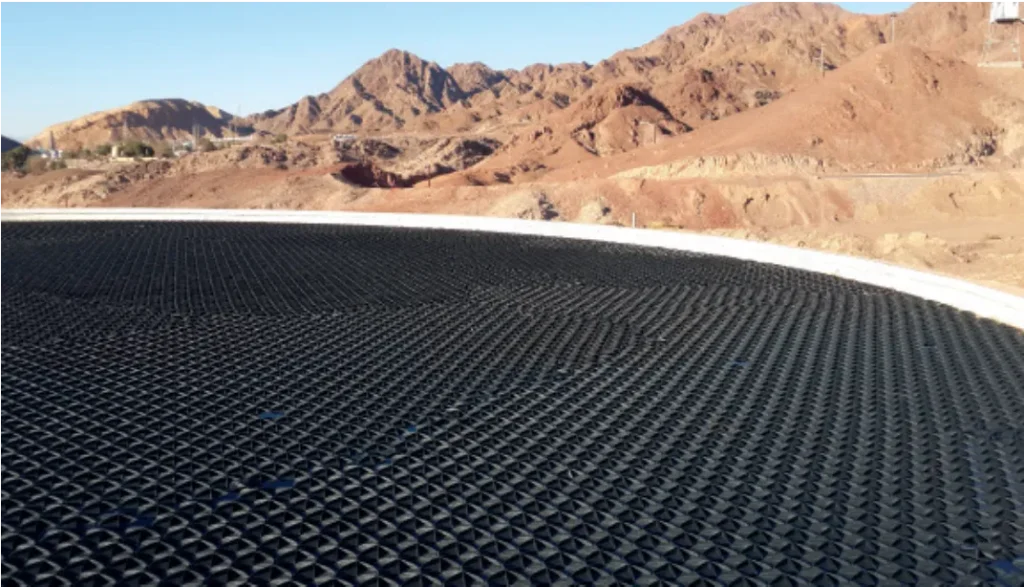

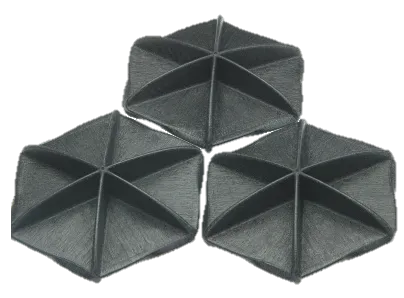

Hexacover

The unique and patented Hexa-Cover Floating Cover is perfect on almost any form of fluid surface. Hexa-Cover Floating Cover is the ideal solution for controlling such things as:

- Odor

- Emission

- Heat loss

- UV effect

- Evaporation

Booster Pumps & Suction Pumps

12" CENTRIFUGAL SELF PRIMING PUMP: MODEL WP300

| DESCRIPTION | 12" Centrifugal Self Priming Pump: MODEL WP300 |

| Pumping capacity | 360 L/sec (max.) (136 BPM) |

| Pump Suction | 300 mm (12 inch) |

| Pump Discharge | 300 mm (12 inch) |

| Total head | 30 mtrs. (max.) |

| Vacuum Motor | 70 cfm |

| Liquid Type/Application | Water (@ 20.00 deg. C) |

8" Water Transfer Pump

| DESCRIPTION | 8" Water Transfer Pump |

| Pumping capacity | 132 L/sec (75 BPM) |

| Pump Suction | 200 mm (8 inch) |

| Pump Discharge | 200 mm (8 inch) |

| Total head | 30 meters |

| Vacuum Motor | 70 cfm | Liquid Type/Application | Water (@ 20.00 deg. C) |

8" Centrifugal Self Priming Pump

| DESCRIPTION | 8" Centrifugal Self Priming Pump |

| Pumping capacity | 132 L/sec (max.) (50 BPM) |

| Pump Suction | 200 mm (8 inch) |

| Pump Discharge | 200 mm (8 inch) |

| Total head | 30 mtrs. (max.) |

| Vacuum Motor | 70 cfm |

| Liquid Type/Application | Water (@ 20.00 deg. C) |

12" Water Transfer Pump

| DESCRIPTION | 12" Water Transfer Pump |

| Pumping capacity | 200 L/sec (75 BPM) |

| Pump Suction | 304 mm (12 inch) |

| Pump Discharge | 304 mm (12 inch) |

| Total head | 88 meters |

| Liquid Type/Application | Water (@ 20.00 deg. C) |

8" Centrifugal Self Priming Pump

| DESCRIPTION | 8" Horizontal, Centrifugal pump |

| Pumping capacity | 212 L/sec (80 BPM) |

| Pump Suction | 254 mm (10 inch) |

| Pump Discharge | 203 mm (8 inch) |

| Total head | 89.5 mtrs. (max.) |

| Liquid Type/Application | Water (@ 20.00 deg. C) |

Baseplate and Build Details:

- Pump and prime mover direct coupled, mounted on a heavy duty, robust common base including forklift pockets or feet allowing fork access for lifting and lifting frame.

- Pump, diesel engine, Skid, bored coupling, coupling gaurd, fuel tank, fuel level gauge, fuel cap, fuel supply and return lines, engine starting batteries, battery box, battery cables, pump discharge pressure gauge, engine muffler, muffler mounting brackets, engine radiator guard, spark arrestor, all necessary nuts, bolts, cables and painting.

- Priming Tank is made of Mild Steel (Stainless Steel Also available) and the internal parts are of Teflon, Stainless steel & Bronze which increase the life and efficiency of the pump. Volute is cast iron and it is designed in such a way that the shape helps to give better discharge. Shaft, Impeller Stuffing box, and all other internal parts are made by stainless steel.

12" Dewatering Pump

| DESCRIPTION | 12" Dewatering Pump |

| Suction & Discharge | 12" * 12" (300 mm * 300 mm) |

| Flow | 1250 m³/hr (131 BPM) |

| Max. Head | 30 meters |

| Vacuum Capacity | 70 cfm (Double Vacuum Motor) |

| Max. Suction Lift | 9 meters |

| Max. Solid Handling | 9" |

| Shaft Seal | Mechanical Seal |

- These pumps are suitable for dewatering, over-pumping sewerage, drainage pumping, irrigation and chiller plants. The suction discharge is 300 x 300 mm with a closed type impeller with a mechanical seal. (Open type impeller also available).

- We are providing pumps as per the demand of the customer requirements, Open Impeller pumps, Electric motor driven pumps, with skid mounted and also available 12” booster.